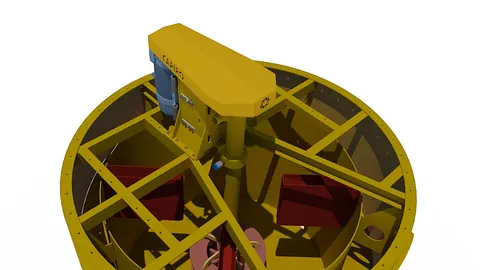

Flotation machines

Flotation machines

The core of an efficient flotation machine is the mechanism itself. Its task is to keep the particles in suspension, while ensuring optimal distribution of large quantities of microscopic air bubbles. Here is a small selection of Capiro's mechanisms, further developed from Aker's original design.Optimize your production with Capiro – quality, innovation, and reliability in every step.Optimize your production with Capiro – quality, innovation, and reliability in every step.

1 liter - 200 m³

We supply flotation units in sizes from 1 liter to 200 m³.

To ensure cost-effective production and easy logistics, the tanks are constructed in sections.

This gives us great flexibility:

- Easy transport: The sections are dimensioned for road transport, even over long

distances. - Local assembly: The design enables efficient assembly close to or directly at the

mine site.

Flexible construction solutions

In addition to our sectioned tanks, we supply fully welded constructions where logistics and

installation conditions allow this. This provides maximum freedom of choice based on the project

location and available infrastructure.

Retrofit mechanism

Easy installation in existing machines.

Features

- Efficient ultrafine air dispersion

- Powerful agitation at the bottom of the flotation cell

- Stable foam layer

- Partially self-priming mechanism

- High-quality material

- Easy and quick maintenance

- Free Flow flotation mechanism

Advantanges

- High recovery rate of valuable minerals

- Strong agitation near the bottom

- Low energy consumption

- Long service life of the flotation mechanism

- Easy start-up after sandy operating conditions

- Low consumption of reagents

- Easy to retrofit into existing flotation machines

- Good handling of coarse particles

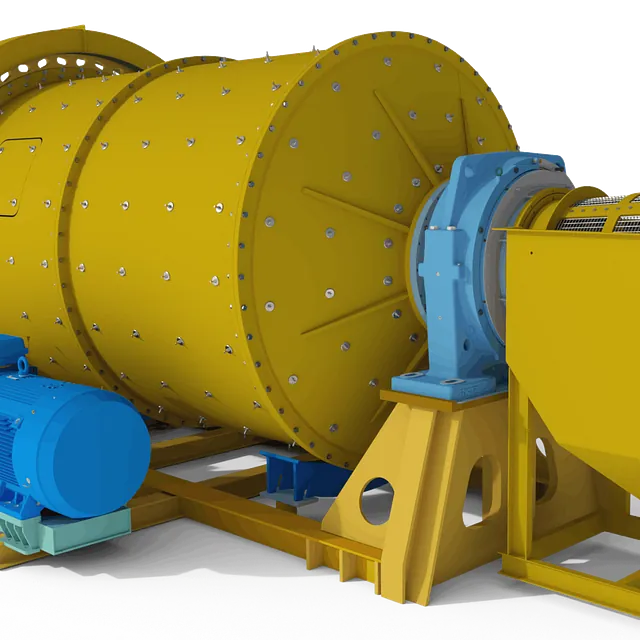

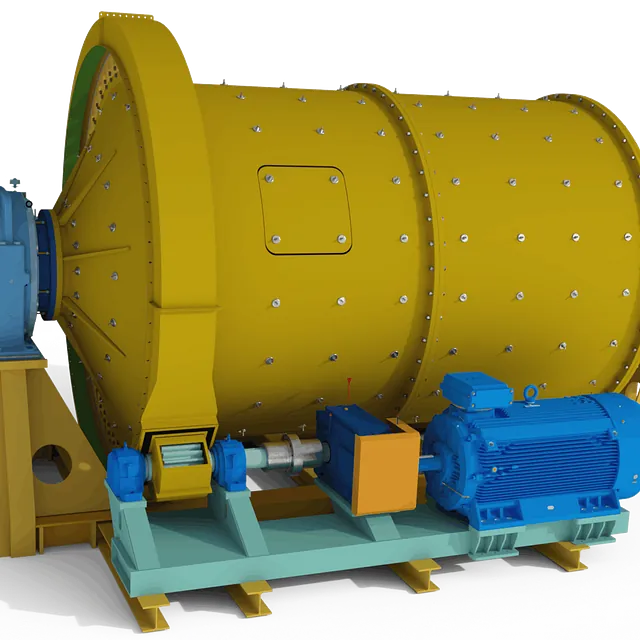

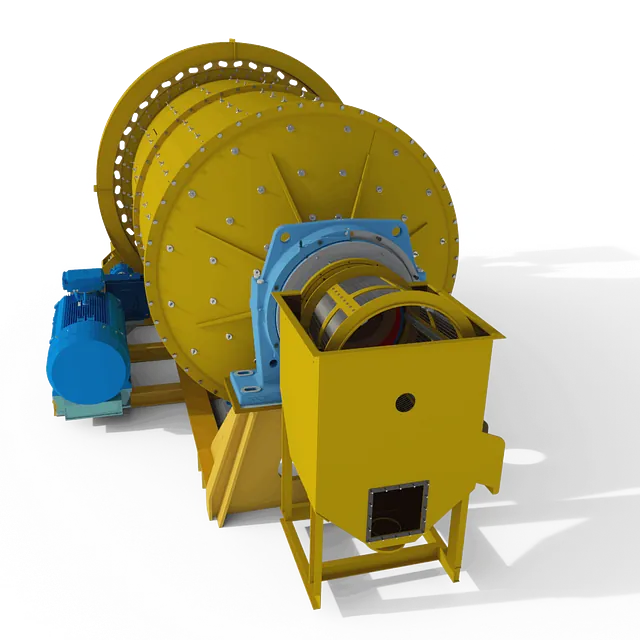

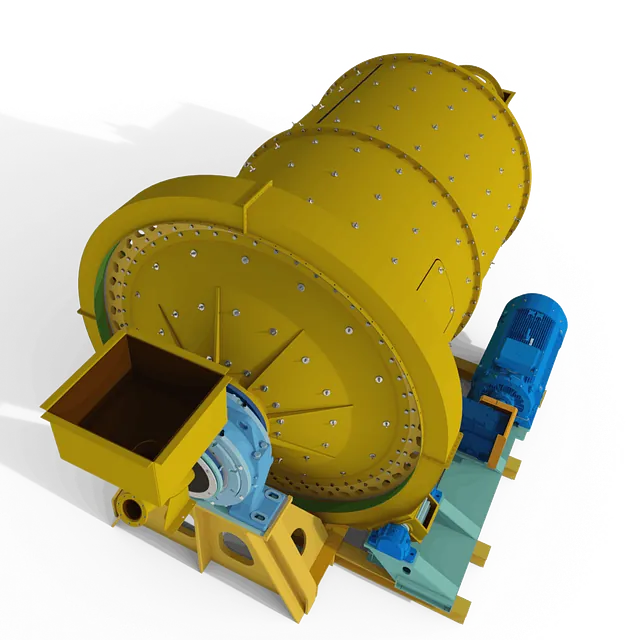

Ball Mills

Ball mills

Capiro manufacture mills according to the desired capacity in dimensions from Ø1.8 to Ø4.5.

We can manufacture in Norway or at our partner in India, depending on what you emphasize.

Do you want weight monitoring or perhaps a specially designed jacking system for use during maintenance - we can deliver everything you want.

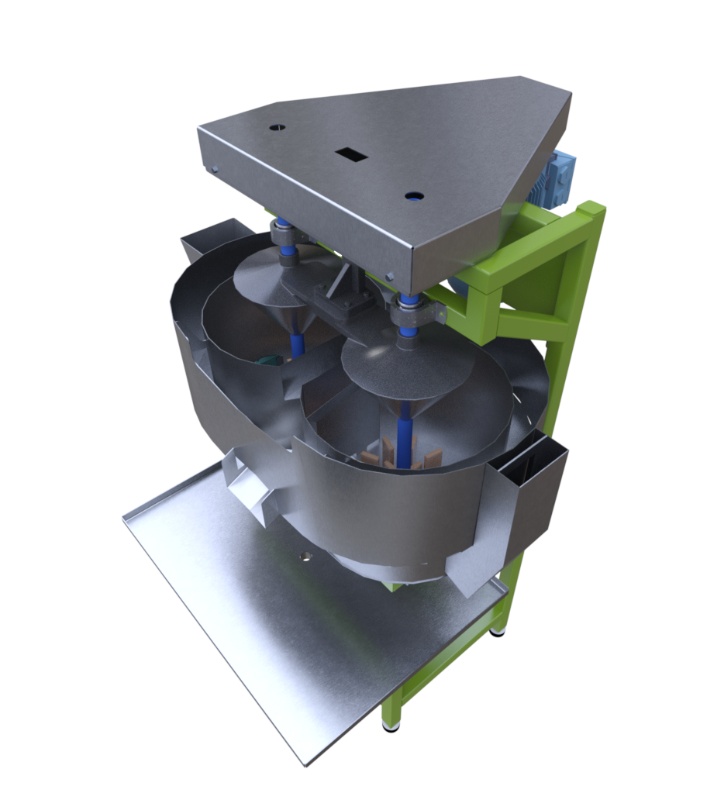

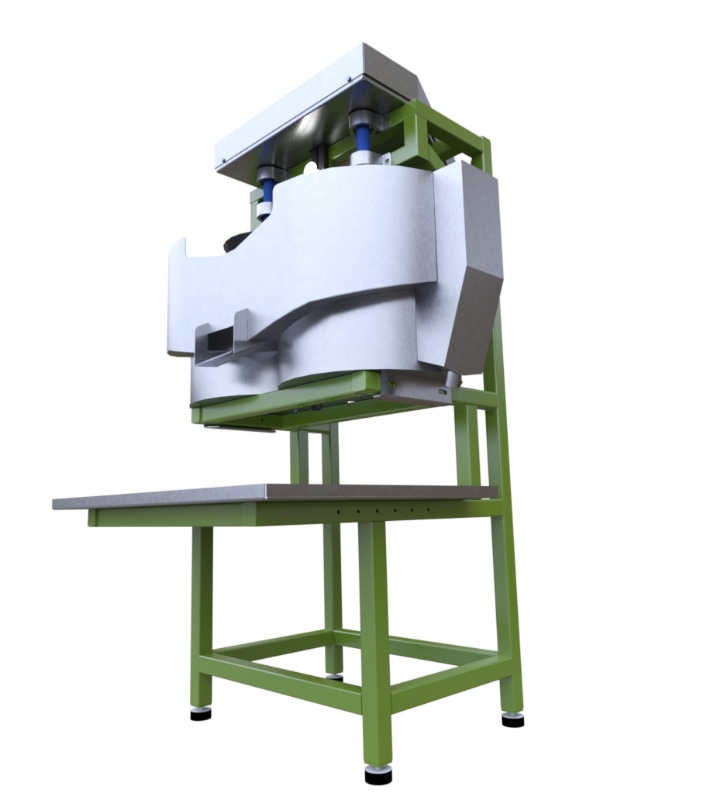

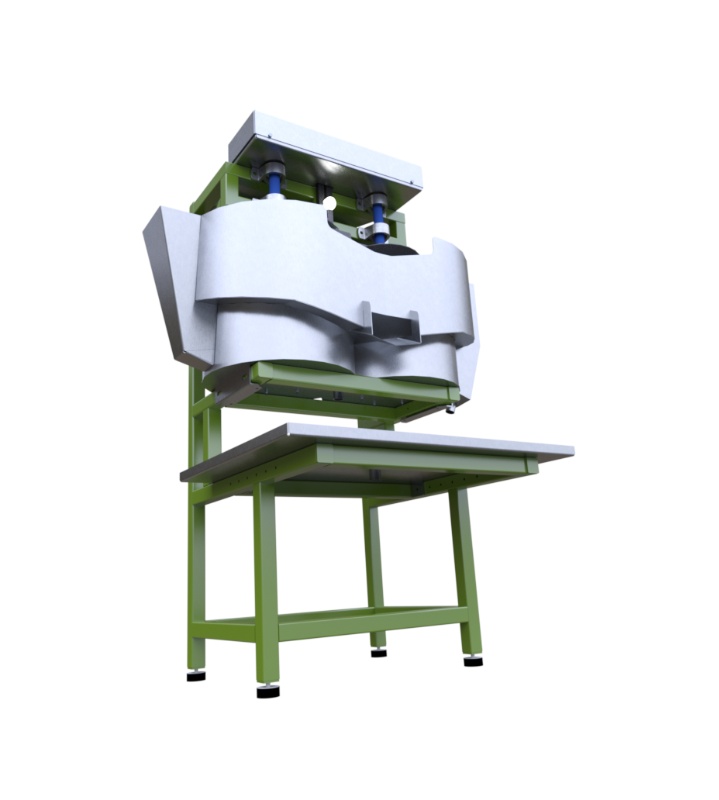

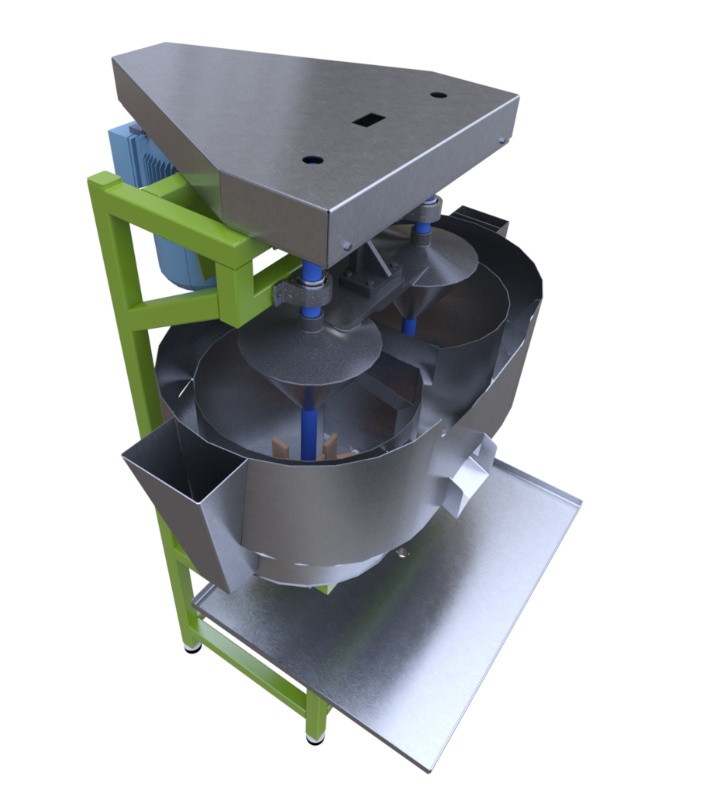

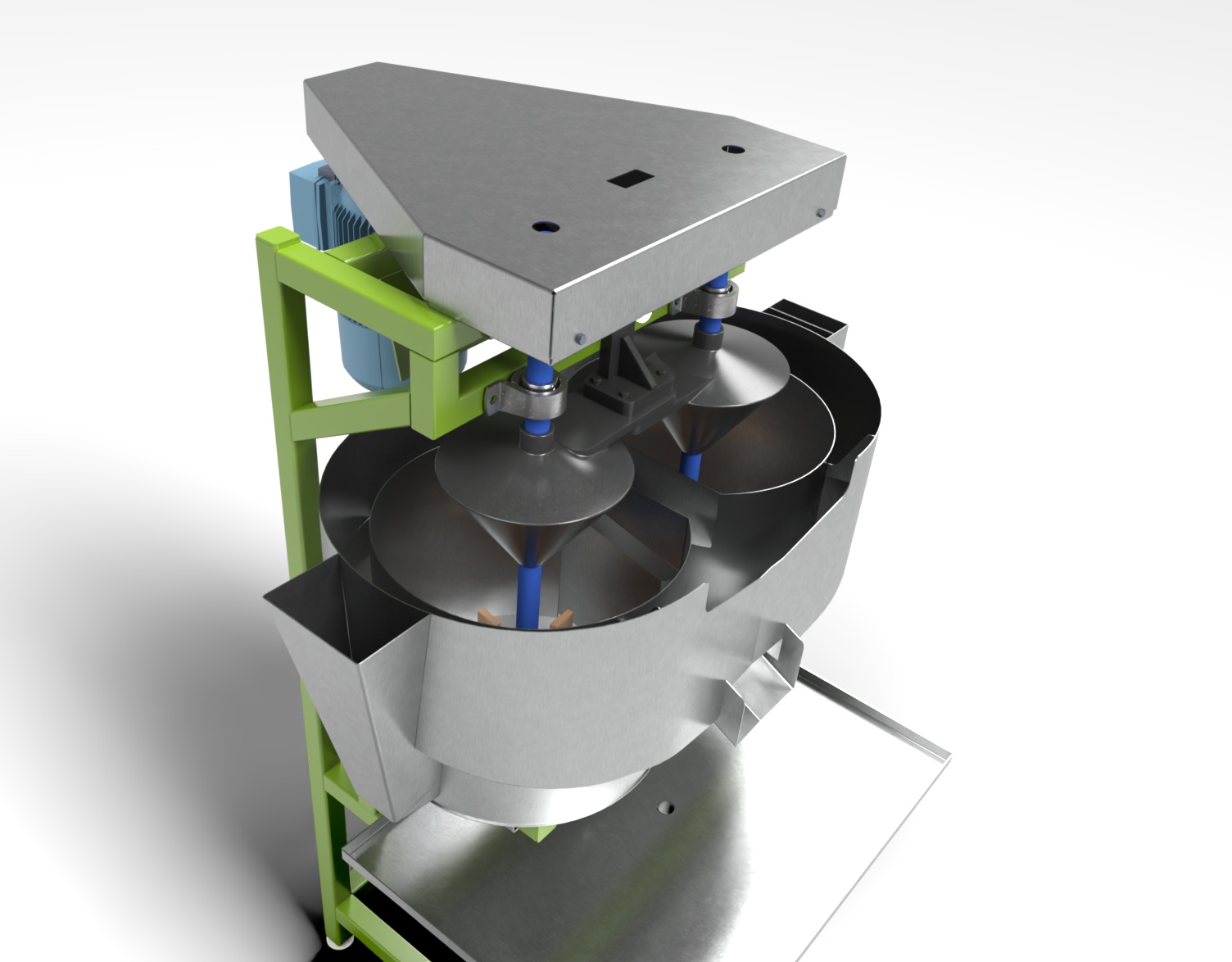

Pilot Machines

Pilot Machines

To achieve optimal results in full-scale plants, precise tests and analyses at lab and pilot scale are essential. Capiro AS offers equipment designed to provide accurate and reproducible data. We combine specialized laboratory equipment with our own technical expertise to deliver everything from single machines to tailor-made solutions for modern laboratories and test facilities.

We offer pilot units with standard sizes of 2x25 liters and 2x40 liters, but can also deliver tailor-made solutions with other volumes if desired.

Customization and design

Using modern 3D tools, we can customize the machines, tank sizes and test setup exactly to your specifications.

Laboratory Equipment

Lab Flotation Machine 30L

This 30 liter flotation machine, stands out with its user-friendly design and advanced technological features. This device provides high efficiency in flotation processes, making it possible to perform larger-scale tests in a laboratory environment.

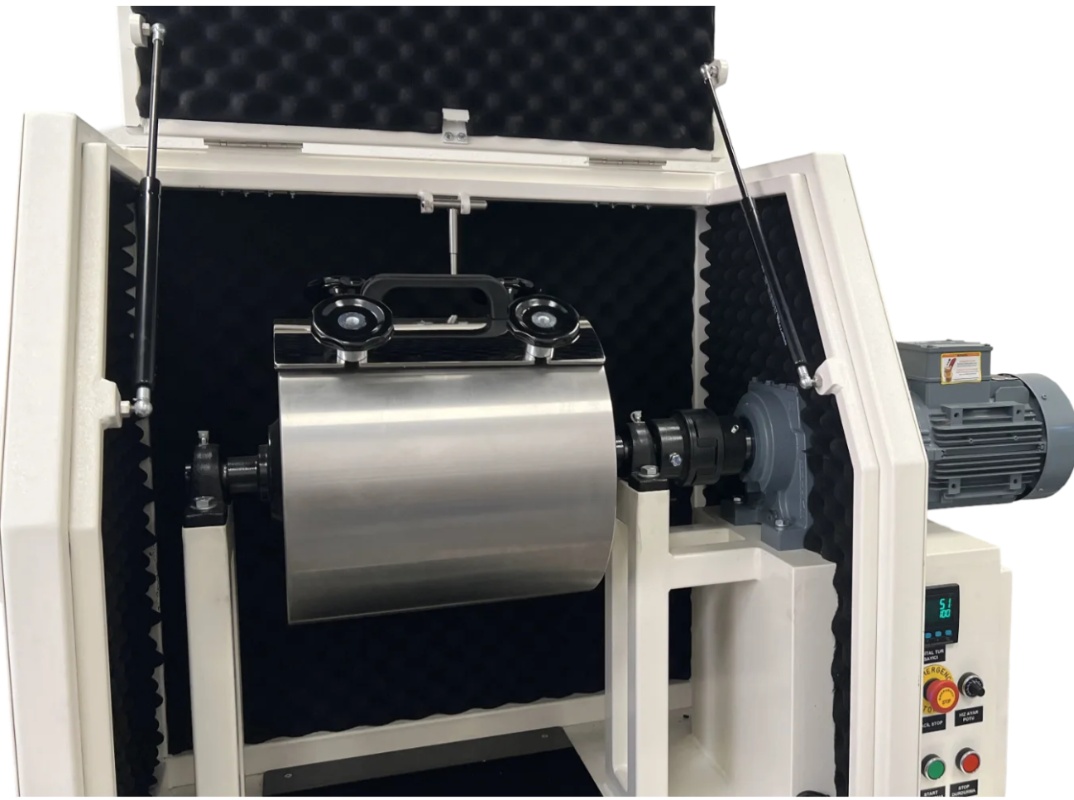

Bond Mill

The Bond Work Index Ball Mill is a high-performance mill designed to measure the grindability of materials and conduct Bond Work Index tests.

Suitable for both wet and dry grinding, this mill can be used not only for Bond Work Index determinations but also as a general-purpose ball mill, with a 22-liter capacity providing versatility across various material types in laboratory studies and grinding applications.

- Ideal for Bond Work Index Tests: Provides an ideal solution for Bond Work Index tests, essential for measuring the grindability of various materials.

- Mill Speed: Infinitely adjustable speed with a speed controller allows for precise rotation adjustment from 0 to 100 rpm, creating suitable grinding conditions for different materials.

- Mill Structure: The cylindrical mill tube, with internal dimensions of Ø305×305 mm (Ø12″×12″), is made of stainless steel (AISI 304), enhancing durability and ease of cleaning.

- Grinding Balls: Supplied with a charge of hardened, heat-treated chrome alloy grinding balls, delivering high efficiency and durability for size reduction.

- Collection and Separation Chamber: Equipped with a product collection and ball separation chamber, making collection and separation simple after grinding.

- Digital Timer: The adjustable digital timer (0-9999 revolutions) enables precise timing control, allowing easy selection of the desired grinding duration for each operation.

These features and advantages make the Bond Work Index Ball Mill an excellent solution for laboratory and small-scale production applications, offering high efficiency and flexibility in sample preparation and size reduction processes.

Lab Table Machine

The Laboratory Flotation Machine, has been modernized and upgraded to provide superior usability, precision, and repeatability in flotation testing. It is designed for mineral processing laboratories that require reliable, efficient, and easy-to-use flotation equipment.

Unlike conventional models, this flotation machine eliminates outdated manual controls and introduces advanced electro-mechanical and digital systems, improving ease of operation and accuracy.

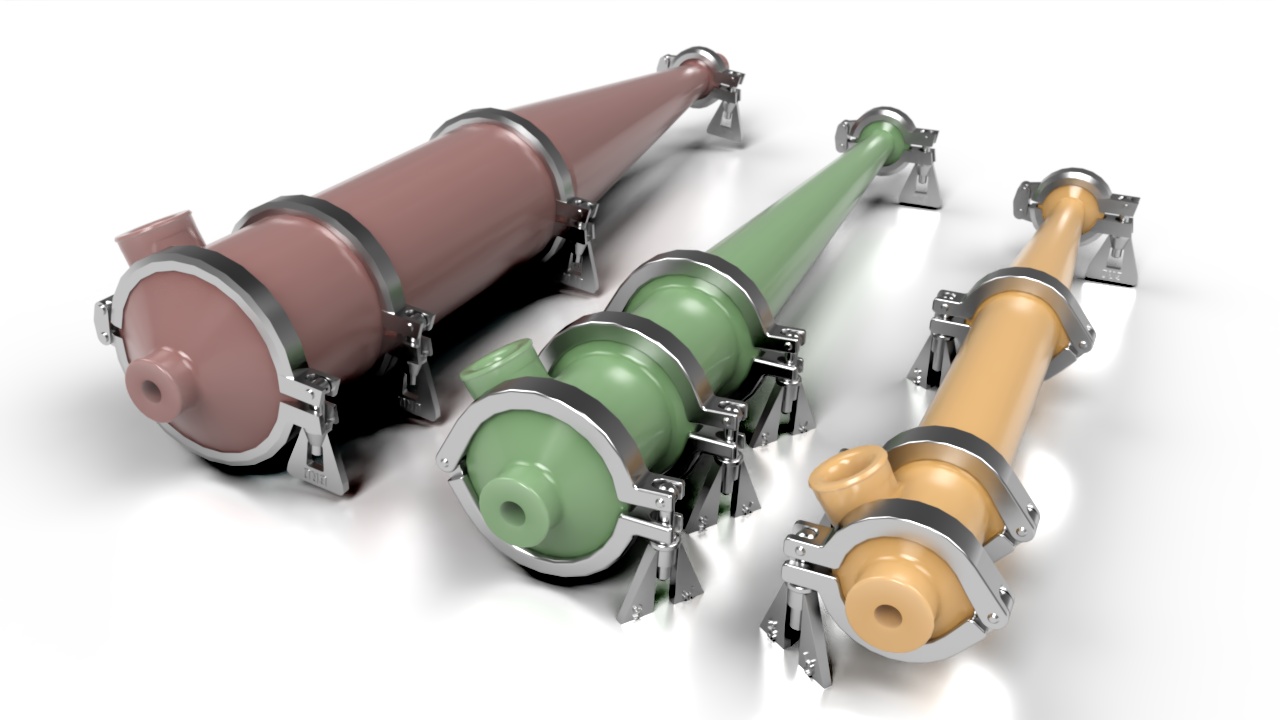

Hydro Cyclones

Hydro Cyclones

We have developed our own hydrocyclones, which are now being tested at a customer with major wear problems.

We know that our cyclones are extremely durable in relation to abrasive particles.

Contact us for more information about this development program.